200-240 t/ụbọchị zuru oke osikapa Parboiling na Milling Line

Nkọwa ngwaahịa

Paddy parboiling dị ka aha na-ekwu bụ a hydrothermal usoro nke starch granules na osikapa na-gelatinized site ngwa nke uzuoku na mmiri ọkụ. Egwe ọka osikapa a na-ekpo ọkụ na-eji osikapa esi mmiri dị ka ihe eji eme ihe, mgbe ihichachara, ịsasa, isi nri, ihicha na ịjụ oyi mgbe ọgwụgwọ okpomọkụ gasịrị, wee pịa usoro nhazi osikapa iji mepụta ngwaahịa osikapa. Osikapa nke agbachara agbachaala etinyela nri osikapa n'ụzọ zuru oke ma nwee ezigbo ụtọ, kwa n'oge esi mmiri, ọ na-egbu ahụhụ ma mee ka osikapa dị mfe ịchekwa.

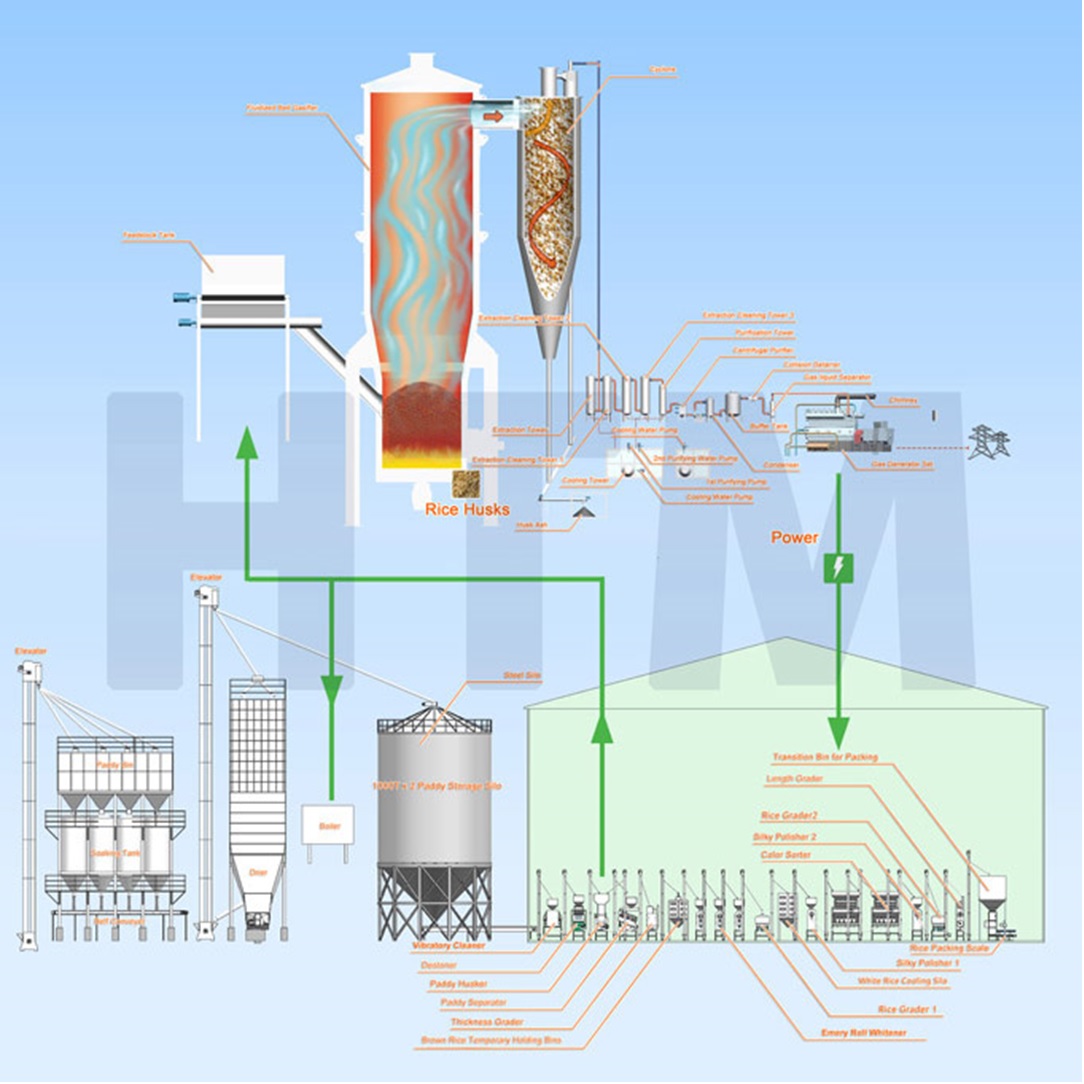

Anyị nwere ike ịnye ụgbọ alannukwu osisi igwe nri osikapa ọgbara ọhụrụna usoro mmepụta ike maka gị ina. Ihe zuru okeakpaka osikapa igwe nri osisia na-ejikarị akụkụ abụọ eme ya: ngalaba ntụ ọka osikapa na ngalaba egwe ọka osikapa.

Nkọwa usoro maka egwe ọka osikapa eghe bụ ndị a

1) Paddy Cleaning: N'oge a, anyị na-ewepụ ihe ndị na-adịghị ọcha na paddy.

Ekwesịrị ibu ụzọ hichaa osikapa ahụ iji wepụ ahịhịa, okwute, eriri hemp, irighiri ihe ndị ọzọ na adịghị ọcha dị ka uzuzu gwakọtara na osikapa. Ọ bụrụ na paddy nwere uzuzu mgbe ọ na-ete ya, ọ ga-emerụ mmiri ma na-emetụta nri osikapa. Ọzọkwa, mgbe usoro nhicha gasịrị, ọdịda nke akụrụngwa nhazi nke ala ma ọ bụ mmebi nke ihe nwere ike ịzere nke ọma, nke bụ isi usoro nke ngwa ngwa osikapa osikapa zuru oke.

2) Paddy Soaking: Ebumnuche nke ịra mmiri bụ ime ka paddy nweta mmiri zuru oke, mepụta ọnọdụ maka pasta starch. N'oge nke starch pasting paddy ga-amịkọrọ n'elu 30% mmiri, ma ọ bụ ọ gaghị enwe ike zuru ezu steamer na paddy na nzọụkwụ ọzọ na otú na-emetụta àgwà osikapa.

a. Site na ikpochapu, okpomọkụ na-adịgide adịgide, na nrụgide nrụgide, osikapa na-etinye mmiri ahụ n'ụzọ zuru ezu n'ime obere oge, nke mere na mmiri nke osikapa ahụ ruru ihe karịrị 30%, nke bụ ọnọdụ dị mkpa maka osikapa osikapa na gelatinized zuru oke. n'oge usoro nri. N'ahịrị mmepụta osikapa parboiled, ngalaba nhazi a bụ akụkụ bụ isi na nke dị mkpa.

b. Dabere na ụdị osikapa dị iche iche na ịdị mma, okpomọkụ na-ekpo ọkụ na-abụkarị ogo 55-70, na oge ịsa ahụ bụ awa 3.5-4.5.

3)Steaming na esi: Mgbe tetara n'ime endosperm enweta mmiri zuru ezu, ugbu a ọ bụ oge na-esi nri na paddy ịghọta starch pasting. Ịkụ ọkụ nwere ike ịgbanwe usoro anụ ahụ nke osikapa ma na-edozi nri, iji mee ka ọnụ ọgụgụ mmepụta dịkwuo elu ma mee ka osikapa dị mfe ịchekwa.

N'ime usoro a, a na-eji uzuoku dị elu na okpomọkụ dị elu. A ghaghị ịchịkwa okpomọkụ, oge, na ịdị n'otu nke steaming nke ọma ka starch dị na osikapa wee nwee ike ịmecha gelatin nke ọma na-enweghị oke.

Mgbe starch gelatinization zuru ezu, na agba nke esichara okokụre parboiled osikapa bụ transperent mmanụ aṅụ na-acha.

Site n'ịgbanwe usoro nri, osikapa parboiled nwere agba dị ọkụ, agba ọchịchịrị na agba gbara ọchịchịrị nwere ike ịhazi dịka ihe ndị ahịa chọrọ.

4) Paddy Drying Parboiled: Ebumnuche nke ihicha bụ ime ka mmiri belata site na gburugburu 35% ruo gburugburu 14%, iji belata mmiri nwere ike ime ka osikapa dị mfe ịchekwa ma bufee ya, ma na-abawanye oke mmepụta, dịka ọnụ ahịa osikapa kacha. enwere ike nweta mgbe a na-egweri osikapa.

Anyị na-eji okpomọkụ nke ọkụ ọkụ n'oge usoro a, a na-atụgharị ya n'ikuku site na onye na-ekpo ọkụ ọkụ, na osikapa na-akpọnwụ na-apụtaghị ìhè, na osikapa a mịrị amị enweghị mmetọ na enweghị isi dị iche iche.

A na-ekewa usoro ihicha ahụ na nkebi abụọ. Nzọụkwụ mbụ bụ ihicha ngwa ngwa, nke na-ebelata mmiri dị n'ime paddy site na ihe karịrị 30% ruo ihe dịka 20%, wee jiri nwayọọ na-ehicha ya iji mee ka paddy ahụ daa ngwa ngwa ma belata ọnụ ọgụgụ mgbawa n'úkwù. Melite ọnụego mita dum.

5) Paddy jụrụ oyi: A na-eziga paddy a mịrị amị na ebe nchekwa kwụ ọtọ maka nchekwa nwa oge ka ọ na-ebelata nke ọma ma mee ka ọ dị jụụ tupu edozi ya. Ụlọ nkwakọba ihe nke cylinder kwụ ọtọ nwere ihe ikuku ventilashị, nke nwere ike wepụ okpomọkụ fọdụrụnụ. Ma mee ka osikapa ahụ dị mmiri nke ọma.

6) Rice Husking na nkewa: Iji igwe hulling osikapa wepụ husk nke paddy a mịrị amị. Mgbe ịsachara na steaming, ọ ga-adị mfe ịkwanye paddy ma chekwaa ume.

A na-ejikarị paddy separator maka ikewa osikapa agba aja na paddy site na ọdịiche ha dị na ike ndọda na ọnụ ọgụgụ esemokwu n'akụkụ atọ: paddy, osikapa agba aja aja, na ngwakọta nke abụọ.

7) Rice Milling: Osikapa osikapa na-eri pearling na-eri oge karịa paddy nkịtị. Ihe kpatara ya bụ na mgbe tetara osikapa dị mfe ịghọ smectic. Iji zere nsogbu a, anyị na-eji igwe igwe na-afụ osikapa ma na-abawanye ọsọ nke igwe ọka osikapa, nnyefe osikapa na-ewere ụdị pneumatic iji belata esemokwu ahụ.

Emepụtara igwe igwe na-egwe ọka osikapa, nke bụ teknụzụ dị elu nke ụwa igwe igwe osikapa ugbu a iji mee ka ọnọdụ osikapa belata, ọdịnaya bran dị ntakịrị, yana mmụba gbajiri ala.

8) Ntucha osikapa: Usoro ihicha osikapa bụ ime ka mmiri dị n'elu osikapa na-egbuke egbuke, bụ nke na-eme ka e guzobe oyi akwa gelatin dị mma nke na-agbatị oge nchekwa. Ụlọ na-egbuke egbuke gbatịrị agbatị iji mepụta osikapa dị mma. Ezi osikapa na-abịa site na igwe na-egbuke egbuke, ọ ga-eme ka osikapa na-egwe ọka ghọọ agba mara mma ma na-egbuke egbuke, si otú a na-eme ka osikapa dịkwuo mma.

9) Rice Grading: A na-eji igwe grading osikapa mee ka osikapa egweri nke ọma na nke ọma n'ime ọtụtụ klas: osikapa isi, nnukwu agbajiri agbaji, ọkara gbajiri agbaji, obere agbajiri, wdg.

10) Nhazi agba osikapa: osikapa anyị nwetara site n'elu nzọụkwụ ka nwere osikapa na-adịghị mma, osikapa agbajiri agbaji ma ọ bụ ụfọdụ ọka ma ọ bụ nkume ndị ọzọ. Ya mere, ebe a, anyị na-eji igwe nhazi agba iji họrọ osikapa na-adịghị mma na ọka ndị ọzọ.

Igwe nhazi agba bụ igwe dị mkpa iji hụ na anyị nwere ike nweta osikapa dị elu. Iji igwe nhazi agba osikapa iji dozie ihe ọjọọ, mmiri ara ehi, chalky, paddy na ihe ndị si mba ọzọ. A nwalere mgbama CCD mgbe ị na-ewepụ oghere. Ọ bụrụ na achọpụta na enwere osikapa ma ọ bụ adịghị ọcha na ihe ndị ahụ, onye na-apụ apụ ga-afụ ngwongwo ndị na-adịghị mma na hopper.

11) Nkwakọ ngwaahịa osikapa emechachara: osikapa emechala ugbu a dịla ezigbo mma! Ka anyị jiri igwe na-atụ ihe na akpaaka anyị mee ka ha bụrụ akpa 5kg 10kg ma ọ bụ 50kg.

Igwe a na-atụnye ihe na-atụnye ihe na-akpaghị aka nwere igbe ihe, ihe ntụtụ, igwe akwa, na eriri ebu. Ọ nwere ike na-arụkọ ọrụ niile nlereanya si osikapa igwe nri ahịrị. Ọ bụ ụdị eletrik, ị nwere ike ịtọ ya dị ka obere kọmputa, mgbe ahụ ọ ga-amalite ịrụ ọrụ. Maka ikike akpa akpa nwere ike ịhọrọ 1-50kg kwa akpa dị ka arịrịọ gị si dị. Site na igwe a, ị ga-enweta osikapa ụdị akpa ma nwee ike ịnye ndị ahịa gị niile osikapa!

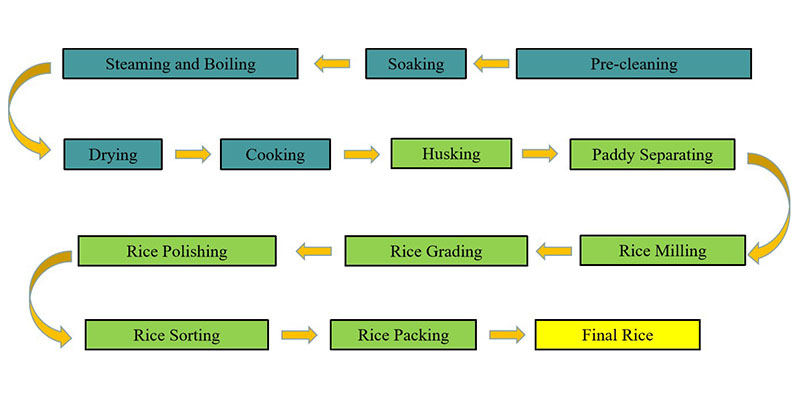

Enwere ike ịhụ site na nhazi nke osikapa na-esi ísì ụtọ na mmepụta nke usoro nchịkọta zuru ezu nke paddy parboiling osisi na-adabere na nkà na ụzụ nhazi nke osikapa ọcha, na-agbakwụnye usoro ọgwụgwọ hydrothermal dị ka nsị, steaming na esi, ihicha na jụrụ oyi. na stewing nwayọọ nwayọọ. Usoro niile nke imepụta osikapa na-agụnye akụkụ abụọ: akụkụ ntụ ọka osikapa na akụkụ osikapa, nke dị ka nke a:

Ngalaba Parboil A.Rice:

Raw Paddy → Na-asachapụ tupu → ịsa mmiri → ịsa mmiri na esi → ihicha → jụrụ oyi → Iji egwe ọka osikapa

Ngalaba Milling B.Rice:

Paddy Parboiled → Nrikọba na nkewa → Egwe ọka osikapa → Ntucha osikapa na grading → Nhazi agba osikapa → mbukota osikapa

Ụkpụrụ nhọrọ nke mmepụta osisi paddy parboiling na-adabere karịsịa na mmepụta na ike nke igwe na-egwe ọka osikapa na-esote. A ga-enwerịrị oke osikapa a chara acha tupu usoro ịgbakọ osikapa enwee ike ịgba ọsọ. Nsonaazụ nke akụrụngwa a na-ebu ụzọ ga-adịrịrịrịrị karịa mmepụta nke igwe osikapa na-esote. Ọ bụrụ na nke ahụ ezughi oke, enwere ike ijikọ nkeji abụọ n'otu n'otu. Mgbe mmepụta na-agbanwe agbanwe, jiri osikapa pre-parboiler na obere ike.

Ọsụ ụzọ na ụlọ ọrụ ahụ, anyị na-etinye aka n'ichepụta ihe ọkụkụ na-enweghị ntụpọ nke Paddy Parboiling Plant. Anyị nwere ike ịnye osisi zuru oke ma na-enye ọrụ ntinye na ọrụ ọzụzụ. Ọ bụrụ na ị nwere mmasị na ọrụ a, biko nweere onwe gị ịkpọtụrụ anyị maka ozi ndị ọzọ.

Atụmatụ

1.Our Parboiling & Drying Plants na-eme ka ihe eji eme ihe na-anwale nke mbụ. Sturdy mere nke ọma wuru na-eme ka ọrụ enweghị nsogbu yana ịdị mma otu ka mma.

2.Uniform steaming nke paddy na-eme ka o kwe omume site na usoro nkesa uzuoku na tankị, Total uniform quality of paddy na usoro nri na ihicha.

3.A na-enye tankị mmiri abụọ n'elu ka mmiri oyi dị mfe ibuli.

4.Ọ dịghị spillage dị ka ụba elu nke osisi ana achi achi mma eruba taper ka mmiri paddy.

5.Uniform ihicha maka osikapa, oké baffles maka ngwa ngwa na otu ebe ihicha enweghị e guzobere ọka gbajiri

6.Factory dabara na ihe ọkụkụ na-agbakọta n'ụzọ zuru ezu bolting na mpịachi ewu, 90% nke ihe na-arụpụtara na anyị factory, minimized oge ewepụtara n'oge echichi.

7.Low ike oriri n'ihi na-arụ ọrụ nke ọma imewe nke blowers na elevators.

Ndị ọrụ na-arụ ọrụ dị ala chọrọ n'ịgba otu ahụ dị ka ọtụtụ operatmachine iji mee ka ha bụrụ akpa 5kg 10kg ma ọ bụ 50kg. Igwe a bụ ụdị eletriki, ị nwere ike ịtọ ya dị ka obere kọmputa, mgbe ahụ ọ ga-amalite ịrụ ọrụ dịka arịrịọ gị si dị. Site na igwe a, ị ga-enweta osikapa ụdị akpa ma nwee ike ịnye ndị ahịa gị niile osikapa!

Eserese isi na-asọpụta bụ: ihicha - ịsa mmiri - uzuoku - ihicha - ihicha - igwe nri - nchacha na grading - nhazi agba - mbukota.

Anyị nwere ike ịnye osisi zuru oke ma na-enye ọrụ ntinye na ọrụ ọzụzụ. Ọ bụrụ na ị nwere mmasị na ọrụ a, biko nweere onwe gị ịkpọtụrụ anyị maka ozi ndị ọzọ.