Usoro Nnụcha mmanụ oriri: Mmiri Degumming

Nkọwa ngwaahịa

Usoro degumming n'ime ụlọ na-emecha mmanụ bụ iwepụ chịngọm chịngọm na mmanụ crude site n'ụzọ anụ ahụ ma ọ bụ kemịkalụ, ọ bụkwa ọkwa mbụ na usoro nnụcha mmanụ / ịdị ọcha. Mgbe ịpịchara na ihe mgbaze sitere na mmanụ mmanụ, mmanụ ahụ na-enwekarị triglycerides na ole na ole na-abụghị triglyceride. Ngwakọta na-abụghị triglyceride gụnyere phospholipids, protein, phlegmatic na shuga ga-emeghachi omume na triglycerides iji mepụta colloid, nke a maara dị ka adịghị ọcha chịngọm.

Ihe na-adịghị mma chịngọm ọ bụghị nanị na-emetụta nkwụsi ike nke mmanụ kamakwa ọ na-emetụta usoro nhazi nke nhazi mmanụ na nhazi miri emi. Dịka ọmụmaatụ, mmanụ na-abụghị degummed dị mfe ịmepụta mmanụ emulsified na usoro nhazi nke alkaline, si otú ahụ na-abawanye ihe isi ike nke ịrụ ọrụ, nkwụsị mmanụ mmanụ, na ihe oriri na-enye aka; na usoro nchacha, mmanụ na-abụghị degummed ga-eme ka oriri nke adsorbent dịkwuo elu ma belata ịdị irè nke discoloring. Ya mere, iwepụ chịngọm dị mkpa dị ka nzọụkwụ mbụ n'ime usoro nchacha mmanụ tupu emebie mmanụ, decolorization mmanụ, na deodorization mmanụ.

The kpọmkwem ụzọ nke degumming gụnyere hydrated degumming (mmiri degumming), acid refining degumming, alkali refining usoro, adsorption usoro, electropolymerization na thermal polymerization usoro. N'ime usoro nhazi mmanụ a na-eri nri, usoro a na-ejikarị eme ihe bụ hydrated degumming, nke nwere ike wepụ hydratable phospholipids na ụfọdụ phospholipids na-abụghị hydrate, ebe ndị fọdụrụ na-abụghị hydrate phospholipids kwesịrị iwepụ site na acid refining degumming.

1. Ụkpụrụ na-arụ ọrụ nke hydrated degumming (mmiri degumming)

Mmanụ crude sitere na usoro mmịpụta ihe mgbaze nwere mmiri soluble mmiri, nke kachasị nke nwere phospholipids, nke a ga-ewepụ na mmanụ ahụ iji mee ka mmiri ozuzo kacha nta na idozi n'oge njem mmanụ na nchekwa ogologo oge. Achịcha chịngọm dị ka phospholipids nwere njirimara nke hydrophilic. Nke mbụ, ị nwere ike ịkpali ma tinye ntakịrị mmiri ọkụ ma ọ bụ ngwọta mmiri electrolyte dị ka nnu & phosphoric acid na mmanụ ọkụ na-ekpo ọkụ. Mgbe oge mmeghachi omume ụfọdụ gasịrị, a ga-ekpochapụ ihe ndị na-adịghị ọcha chịngọm, belata ma wepụ ya na mmanụ. N'ime usoro nsị nke hydrated, ihe adịghị ọcha bụ nke kachasị phospholipid, yana protein ole na ole, glyceryl diglyceride, na mucilage. Ihe ọzọ bụ na enwere ike ịhazi chịngọm ndị a amịpụtara ka ọ bụrụ lecithin maka nri, nri anụmanụ ma ọ bụ maka ojiji teknụzụ.

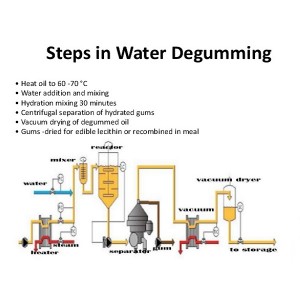

2. Usoro nke hydrated degumming (mmiri degumming)

Usoro nkwụsị mmiri na-agụnye ịgbakwunye mmiri na mmanụ crude, na-eme ka mmiri na-edozi mmiri, wee wepụ ọtụtụ n'ime ha site na nkewa centrifugal. The ìhè na-adọ mgbe centrifugal nkewa bụ crude degummed mmanụ, na arọ agba mgbe centrifugal nkewa bụ a Nchikota mmiri, mmiri soluble components na entrained mmanụ, mkpokọta zoro aka dị ka "gums". A na-akpọnwụ mmanụ crude ma mee ka ọ dị jụụ tupu ezipụ ya na nchekwa. A na-atụgharị chịngọm azụ na nri.

N'ime ụlọ ọrụ na-edozi mmanụ, igwe na-eme ka mmiri na-ekpo ọkụ nwere ike iji igwe deacidification mmanụ, igwe decolorization, na igwe deodorizing, na igwe ndị a bụ ihe mejupụtara ahịrị mmepụta mmanụ na-eme ka mmanụ dị ọcha. A na-ekewa ahịrị na-eme ka ọ dị ọcha n'ụdị na-adịghị akwụsị akwụsị, ụdị nke na-aga n'ihu na nke na-aga n'ihu n'ụzọ zuru oke. Ndị ahịa nwere ike ịhọrọ ụdị dị ka ikike mmepụta ha chọrọ: ụlọ ọrụ mmepụta ihe nke nwere ikike mmepụta nke 1-10t kwa ụbọchị kwesịrị ekwesị maka iji ngwa ụdị oge, 20-50t kwa ụbọchị ụlọ ọrụ dị mma maka iji ụdị ngwá ọrụ na-aga n'ihu, na-emepụta. ihe karịrị 50t kwa ụbọchị kwesịrị ekwesị maka iji ụdị akụrụngwa na-aga n'ihu zuru oke. Ụdị nke a na-ejikarị eme ihe bụ ahịrị mmepụta degumming hydrated na-anọpụ iche.

Nka nka

Ihe ndị bụ isi nke hydrated degumming (mmiri degumming)

3.1 Mpịakọta mmiri agbakwunyere

(1) Mmetụta nke mmiri agbakwunyere na flocculation: Ọnụ mmiri kwesịrị ekwesị nwere ike ịmepụta usoro liposome multi-layer kwụsiri ike. Mmiri na-ezughị ezu ga-eduga n'ịgbasa mmiri na-adịghị agwụ agwụ na colloidal flocculation ọjọọ; Mmiri buru ibu na-eme ka emulification mmanụ-mmiri, nke siri ike ikewapụ adịghị ọcha na mmanụ.

(2) Mmekọrịta dị n'etiti ọdịnaya mmiri agbakwunyere (W) na ọdịnaya glum (G) na ọnọdụ okpomọkụ dị iche iche:

| obere okpomọkụ hydration (20 ~ 30 ℃) | W= (0.5~1) G |

| hydration nke ọkara (60 ~ 65 ℃) | W= (2-3) G |

| elu okpomọkụ hydration (85 ~ 95 ℃) | W= (3-3.5) G |

(3) Nnwale nlele: Enwere ike ikpebi oke mmiri agbakwunyere kwesịrị ekwesị site na nlele nlele.

3.2 Ọnọdụ okpomọkụ

Ọnọdụ okpomọkụ na-arụ ọrụ na-adaba na okpomọkụ dị oke egwu (maka flocculation ka mma, okpomọkụ ọrụ nwere ike ịdị elu karịa okpomọkụ dị oke egwu). Na okpomọkụ ọrụ ga-emetụta ọnụ ọgụgụ nke mmiri agbakwunyere mgbe okpomọkụ dị elu, oke mmiri dị ukwuu, ma ọ bụghị ya, ọ dị ntakịrị.

3.3 Ike nke ngwakọta hydration na oge mmeghachi omume

(1) Inhomogeneous hydration: Gum flocculation bụ mmeghachi omume dị iche iche na interface mmekọrịta. Iji mee ka steeti emulsion mmanụ-mmiri kwụsiri ike, ịgwakọta ngwakọta ahụ nwere ike ime ka ụmụ irighiri mmiri ahụ gbasasịa n'ụzọ zuru oke, ngwakọta n'ibu chọrọ ka ọ sie ike karịchaa mgbe ọnụọgụ mmiri agbakwunyere buru ibu na ọnọdụ okpomọkụ dị ala.

(2) Ike nke ngwakọta hydration: Mgbe ị na-agwakọta mmanụ na mmiri, ọsọ na-akpali akpali bụ 60 r / min. Na oge nke flocculation na-amụba, mkpali ọsọ bụ 30 r / min. Oge mmeghachi omume nke ịgwakọta hydration bụ ihe dịka nkeji iri atọ.

3.4 Electrolytes

(1) Ụdị electrolytes dị iche iche: Nnu, alum, sodium silicate, phosphoric acid, citric acid na dilute sodium hydroxide solution.

(2) Isi ọrụ nke electrolyte:

a. Electrolytes nwere ike imebi ụfọdụ ụgwọ eletrik nke ụmụ irighiri ihe colloidal ma kwalite ụmụ irighiri ihe colloidal na sedimentate.

b. Iji tọghata phospholipids na-adịghị hydrated ka ọ bụrụ phospholipids hydrated.

c. Alum: enyemaka flocculant. Alum nwere ike ịmịnye pigmenti na mmanụ.

d. Iji chelate na ion ígwè ma wepụ ha.

e. Iji kwalite colloidal flocculation nso ma belata ọdịnaya mmanụ nke flocs.

3.5 Ihe ndị ọzọ

(1) Mmanụ na-adị n'otu: Tupu hydration, a ga-agbanye mmanụ crude nke ọma ka enwere ike kesaa colloid n'otu n'otu.

(2) okpomọkụ nke mmiri agbakwunyere: Mgbe hydration, okpomọkụ nke ịgbakwunye mmiri kwesịrị hà nhata ma ọ bụ dịtụ elu karịa okpomọkụ mmanụ.

(3) agbakwunyere ogo mmiri

(4) Nkwụsi ike ọrụ

N'ikwu okwu n'ozuzu, a na-ekpebi teknuzu teknụzụ nke usoro degumming dị ka mma mmanụ si dị, na ihe dị iche iche nke mmanụ dị iche iche na usoro nkwụsịtụ dị iche iche. Ọ bụrụ na ị nwere mmasị n'ịnụcha mmanụ, biko kpọtụrụ anyị na ajụjụ gị ma ọ bụ echiche gị. Anyị ga-ahazi ndị injinia ọkachamara anyị ka ha hazie ahịrị mmanụ kwesịrị ekwesị nke ejiri akụrụngwa na-edozi mmanụ kwekọrọ maka gị.