Osisi mmanụ na-agbaze: Loop ụdị Extractor

Nkọwa ngwaahịa

Ihe mgbaze bụ usoro iji wepụ mmanụ n'ihe ndị na-ebu mmanụ site na ihe mgbaze, ihe mgbaze na-ahụkarị bụ hexane. Osisi na-amịpụta mmanụ ihe oriri bụ akụkụ nke ụlọ ọrụ na-edozi mmanụ ihe oriri nke emebere iji wepụ mmanụ ozugbo site na mkpụrụ mmanụ nwere ihe na-erughị 20% mmanụ, dị ka soybean, mgbe ọ gbasasịrị. Ma ọ bụ, ọ na-ewepụta mmanụ site na achicha nke osisi a pịaraburu ya ma ọ bụ nke a pịara ya nke ọma nwere ihe karịrị 20% mmanụ, dị ka sunflower, ahụekere, mkpụrụ owu na ihe ndị ọzọ dị iche iche.

N'oge nkà na ụzụ nke leaching, usoro nke leaching bụ akụkụ kachasị mkpa nke teknụzụ dum, n'agbanyeghị na ọ bụ maka ịpụpụ kpọmkwem site na flacks, leaching nke achicha a na-agbanye tupu oge eruo ma ọ bụ leaching nke ihe na-afụ ụfụ, nke ụkpụrụ ọrụ bụ otu, ma tupu ọgwụgwọ nke ihe dị iche iche, n'ihi ya, e nwere ụfọdụ dị iche iche na nhazi ọnọdụ na nhọrọ nke equipments si dị iche iche ihe.

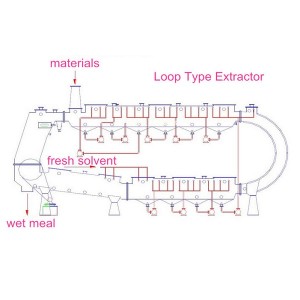

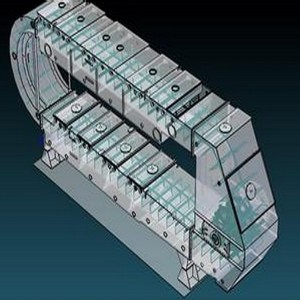

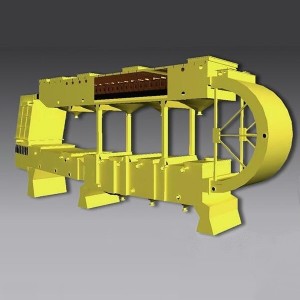

The loop ụdị extractor na-emegharị nnukwu mmanụ osisi maka ịwepụta, ọ na-anabata usoro ịnya ụgbọ ala, ọ bụ otu usoro mmịpụta nwere ike dị na osisi mmịpụta ihe mgbaze. Nhazi loop ọhụrụ ahụ na-eme ka ike dị ntakịrị, na-edozi obere ma na-ebelata mkpọtụ. Enwere ike gbanwee ọsọ ntụgharị nke loop-ụdị extractor na-akpaghị aka dabere n'ọtụtụ mkpụrụ mmanụ na-abata iji hụ na ọkwa nke biini ahụ kwụsiri ike. Nke a ga-enyere aka na-etolite micro-adịghị mma-nrụgide na extractor iji gbochie mgbapụ nke ihe mgbaze gas. Kedu ihe ọzọ, njirimara kachasị ya bụ mkpụrụ mmanụ sitere na ngalaba na-ehulata ka ọ ghọọ substratum, na-eme ka ịwepụta mmanụ dịkwuo mma, oyi akwa na-emighị emi, nri mmiri na-enweghị ihe mgbaze, mmanụ fọdụrụnụ na-erughị 1%.

Atụmatụ nke loop ụdị extractor

1. Loop ụdị extractor adopts yinye nnyefe, ụdị ọhụrụ nke pụrụ iche okirikiri usoro, onwem na ugboro ugboro moto na-achịkwa, obere ike oriri, obere adiana ọsọ, kwụsiri ike na-agba ọsọ na-enweghị mkpọtụ.

2. Usoro nri nwere ike na-akpaghị aka gbanwee ọsọ ọsọ nke isi moto dị ka ihe dị iche iche na ego si dị iche iche iji nọgide na-enwe ọkwa ụfọdụ nke tankị nchekwa. Ọ na-enyere aka guzobe nrụgide micro na-adịghị mma n'ime onye na-ewepụta ihe iji gbochie ntapu nke ihe mgbaze.

3. Mgbasa mmanụ miscella dị elu na-enyere aka belata ntinye ego nke ihe mgbaze ọhụrụ, ibelata ọdịnaya mmanụ fọdụrụ na nri, ma mee ka ntinye nke miscella dịkwuo elu, ma belata ego na-ekpofu ọkụ iji nweta ebumnuche nke ịzọpụta ike.

4. The ihe oyi akwa nke extractor e mere dị ka ala na-eji percolation leaching. A ga-atụgharị ihe ndị ahụ na ngalaba na-ehulata iji belata akụkụ kpuru ìsì nke leaching. Otú ọ dị, n'ọnọdụ dị ịrịba ama dregs na Miscella dị elu, a na-ekpochapụ dregs nke ọma tupu ịbanye na usoro evaporation.

5. Ọ na-ewe nrụgide na-adịghị mma zuru oke na-ekpochapụ na usoro evaporation, na-arụ ọrụ dị elu nke kpo oku ma na-enyere aka melite mma mmanụ leached.

6. Ọ na-ewe kpam kpam teknụzụ nrụgide na-adịghị mma nke usoro nchịkọta, na-arụ ọrụ dị elu nke okpomọkụ.

7. A na-eji igwe anaghị agba nchara kwụ ọtọ multitubular condenser na ọnụego mgbake dị elu. Mpaghara dị obere maka enyemaka condenser iji chekwaa itinye ego nke ọrụ ahụ.

8. Usoro na ogbako ahụ nwere ike ịchịkwa kọmputa, gụnyere okpomọkụ, nrụgide, ọkwa mmiri mmiri na mmiri na-asọpụta, wdg .. A na-enye ihe ndekọ ihe ngosi na-agbanwe agbanwe nke mmepụta ihe mmepụta ihe, ndekọ ọkwa nke nkwụsị na nkwụsị, a na-enye mpempe akwụkwọ data nlekọta. site na nchekwa data agbakwunyere. The njikwa kabinet na-achịkwa software, nnukwu ihuenyo nlekota oru, ụdị nke data, akụkọ na kwekọrọ ekwekọ obibi akwụkwọ, ga-synchronous egosipụta site n'ime ime launching akara usoro, hazie mmejọ nchoputa na nyochaa n'ime ime na ogologo anya, ka egosipụtara n'oge na n'ụzọ dị irè technology. nkwado.

9. Were paroline maka mgbake mgbaze site na ikuku ikuku, ikuku ikuku nwere obere ihe mgbaze.

10. Nhazi nke ogbako nwere ezi uche, mara mma na mmesapụ aka.

| Nlereanya | Ike (t/d) | Ike (kw) | Ngwa ngwa | Mark |

| YHJ100 | 80-120 | 4 | Jiri maka iwepụta mmanụ nke mkpụrụ mmanụ dị iche iche | Kwesịrị ekwesị maka ezigbo mkpụrụ mmanụ dị ka soybean

|

| YHJ150 | 140-160 | 5.5 | ||

| YHJ200 | 180-220 | 7.5 | ||

| YHJ300 | 280-320 | 11 | ||

| YHJ400 | 380-420 | 15 | ||

| YHJ500 | 480-520 | 15 |